Introduction

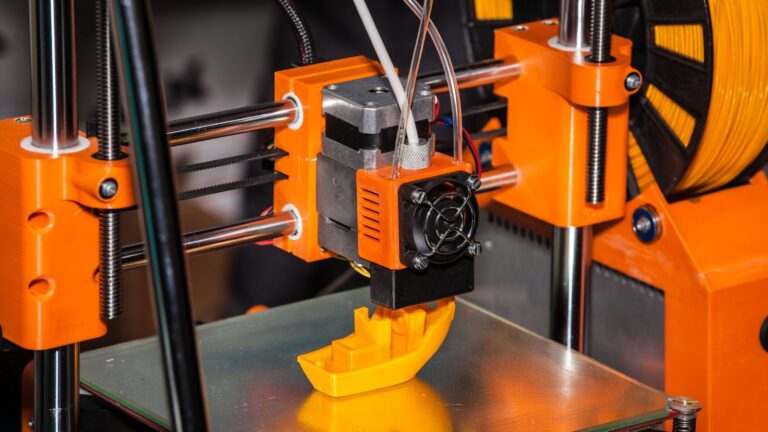

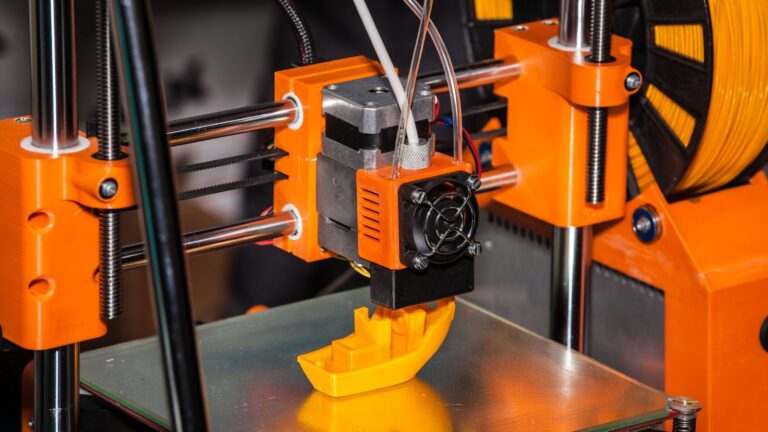

The word Rapid prototyping is used when we physically create an object that was originally made on a 3D design software.

Rapid prototyping has become more adopted, it is an even bigger part of education in 3D printing.

In the article, we have created an outline of this technique, so you can begin creating your own.

How does Rapid prototyping work?

Rapid prototyping is done, usually with the following steps:

- Ideation and design: This is when the design engineer thinks up an idea and creates the set in 3D format and then Autocad software like Solid works or fusion 360.

- This 3D file is then fed into a 3D printer, and then fabricated.

- The physical part that is produced is then tested for consistency and other design and quality parameters that the team may be tracking.

- Depending on the feedback receipt, the above three steps are recreated until the team fields they get an end product that falls within their expected parameters of quality guidelines.

Other technologies are also used in Rapid prototyping a person, and 3D printing. These include casting, moulding, CNC machining, extruding, etc.

What Industries use rapid prototyping? Some examples of rapid prototyping

Whether 3D printing is an effective solution for mass manufacturing is something not everyone agrees on. However, before you produce a product on mass scale, you first need to have an original copy. that is where rapid prototyping comes in.

Multiple industries used Rapid prototyping to speed up their manufacturing processes, deploy new innovations faster, as well as to conduct research on new products.

Industries like healthcare transportation consumer goods and large-scale manufacturing all utilized Rapid prototyping as a part of their product development.

The relationship between Rapid prototyping and 3D printing

Rapid prototyping and 3D printing have a very close relationship. In a lot of design and manufacturing circles, these two terms are synonymous.

In fact, 3D printing is a necessary part of rapid prototyping, as it’s the quickest process to turn your design into physical products.

Output is created in a matter of hours, if not days. This means the design team can start making adjustments to the design and get successive samples made quickly.

This means we can get to the perfect product faster.

What are the advantages of rapid prototyping?

Rapid prototyping has the following advantages over traditional prototyping techniques:

- Faster product development: As more updated and improved copies are created in less time, we are able to save on the time-consuming process of product development. Rapid prototyping has cut development times by months and years in the case of some industries. This due to is a large amount of input we have with editing digital files with computer-aided design software.

- Less Wastage of material: Earlier and conventional forms of prototyping used wood or metal to create the prototype. As the rate of improvement of each iteration is higher than the conventional methods, we end up using way less material to create the same product. This provides both an opportunity to reduce costs and to make manufacturing more sustainable.

- Economically viable: Rapid prototyping helps the bottom line in multiple ways. You save up first with saving by hiring fewer people. You also don’t need to buy expensive and specialized equipment. Since Rapid prototyping only needs a design team and a 3D printer, you also save a lot of space and valuable real estate. Best of all, as you can create faster products faster, you get to experiment with a variety of design options and ideas.

How much does Rapid prototyping cost?

The cost of repeat prototyping depends on a variety of factors. Major factors include:

- Size

- Material used

- Type of surface finishing

- Number of parts in assembly

- Extra processes (like machining or heat treatment)

Professional Rapid prototyping services from 3D motifs

The designer and production team need to be in sync. This is because rapid prototyping is the first step in physical product development.

The requirement and objectives should be clear. Clearer ideas lead to faster production time, and save material, which translates to significant cost reduction.

The prototyping team should be experienced in the processes and should know common pitfalls in the rapid prototyping process.

In our journey as a 3D printing service provider, we have helped our clients with design and printing solutions and we know how to match customer expectations with end results.

Our Rapid prototyping services can help you in proceeding from Idea to end result, so reach out to our team today and that’s get prototyping!